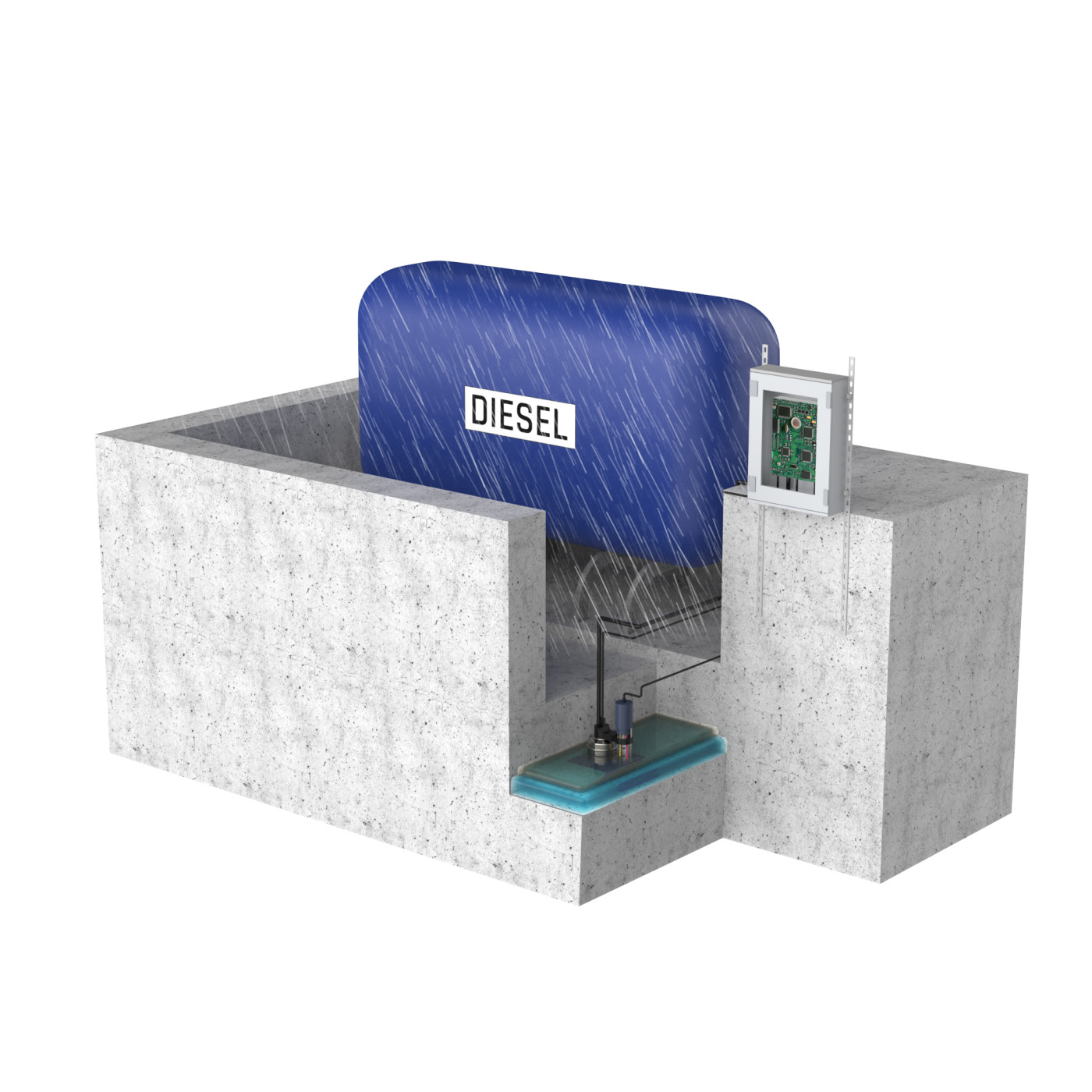

Bund Dewatering

Monitor and dewater bunds to retain 110% capacity bund contents, safely pumping water into drainage system.

Aquasentry manufacture and supply a diverse range of pollution prevention equipment and liquid monitoring solutions.

If you’re interested in discovering how we can help protect your business with our range of products and services, fill in the form and a member of our team will get in contact with you to discuss further.